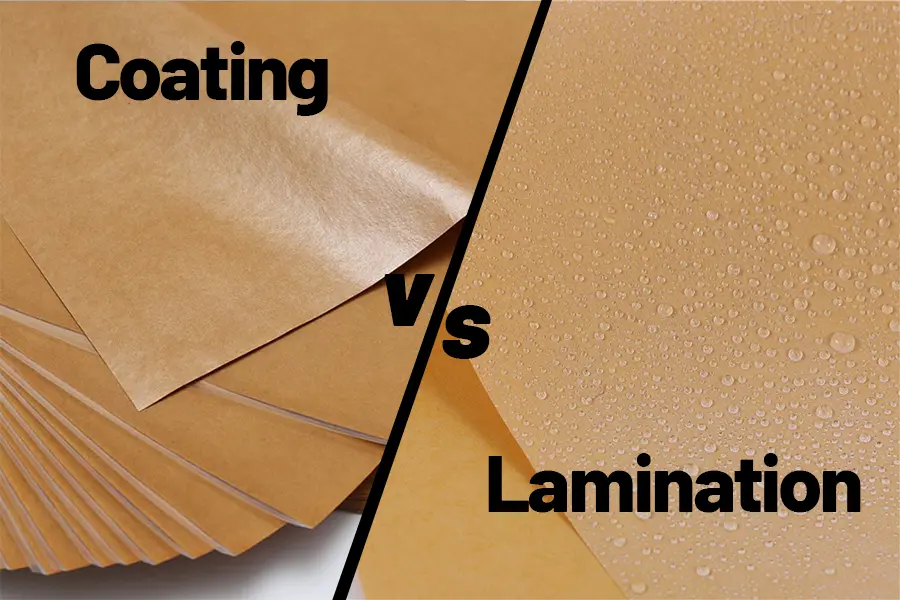

Choosing the right protection for your paper food packaging – boxes, cups, wraps, or trays – is crucial. You need it to keep food fresh, safe, and looking great. Two common methods are Lamination and Coating. They sound similar, but work differently. Let’s break it down simply!

Thank you for reading this post, don't forget to subscribe!1. Coating (Often Called PE Coating or Extrusion Coating):

- How it works: Liquid plastic (usually Polyethylene – PE) is melted and applied directly onto the paper surface in a very thin, even layer. It then cools and bonds to the paper.

- What it looks/feels like: Keeps the natural feel of the paper underneath. The surface is smooth but you can still sense the paper texture. It often has a slight shine.

- Best for:

- Excellent water and grease resistance (great for coffee cups, soup containers, burger wraps).

- Good heat sealability (easy to close packaging securely).

- Cost-effective for many standard applications.

- Good moisture barrier to keep food fresh.

- Things to note: Uses plastic, though often in a thin layer. Can sometimes feel a bit “waxy.”

2. Lamination (Often Called Film Lamination or PP Lamination):

- How it works: A pre-made, thin plastic film (often Polypropylene – PP or Polyester – PET) is glued onto the paper surface using heat and pressure.

- What it looks/feels like: Creates a distinct, separate plastic layer on top. The surface is very smooth, often glossy, and feels more distinctly “plastic.” Hides the paper texture underneath completely.

- Best for:

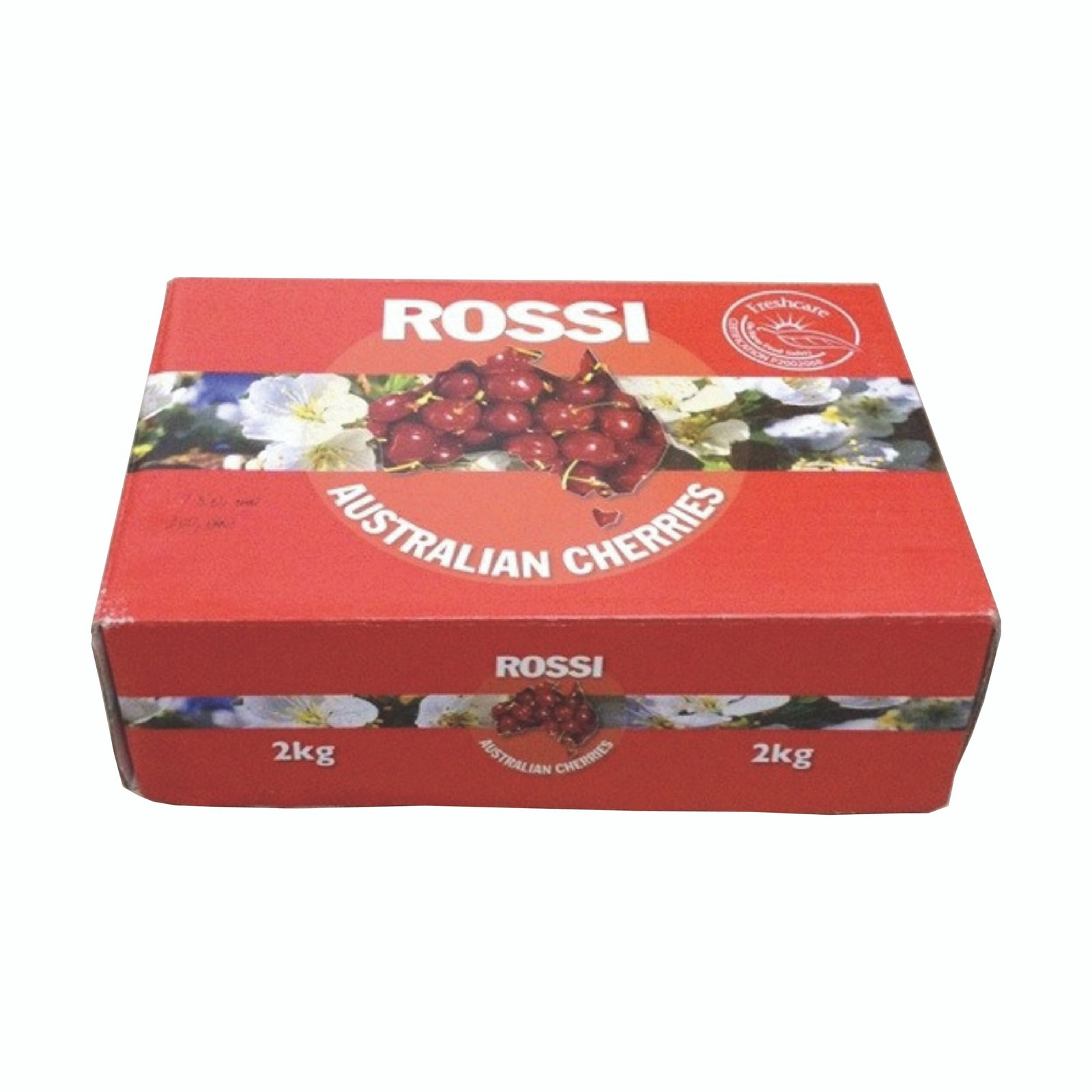

- Super high gloss and vibrant print quality (makes colors pop!).

- Very high grease resistance.

- Excellent barrier against oils, air, and some smells.

- Creates a very strong, durable, and stiff structure.

- Can offer unique finishes (matte, glossy, soft-touch).

- Things to note: Generally uses slightly more plastic than coating. Can feel less “natural” than coated paper. Might be slightly more expensive than coating for some items.

Quick Comparison:

| Feature | Coating (PE) | Lamination (PP/PET Film) |

| Feel | Paper-like, smooth | Distinct plastic layer, very smooth |

| Look | Slight shine, shows paper texture | High gloss/matte, hides texture |

| Print Quality | Good | Excellent, vibrant colors |

| Water Barrier | Excellent | Very Good |

| Grease/Oil Barrier | Excellent | Excellent |

| Structure | Standard | Stronger, Stiffer |

| Cost (Generally) | Often Lower | Often Higher |

| Eco-Impact | Less plastic (thin layer) | More plastic (film + adhesive) |

So, Which One is Right For YOU?

There’s no single “best” choice! It depends on your specific needs:

- Need great grease resistance for burgers or fries at a good price? Coating is likely perfect.

- Want stunning, high-gloss photos on a premium box or bag? Lamination is the way to go.

- Need the strongest possible structure? Lamination adds rigidity.

- Prioritize a more natural paper feel? Coating keeps that texture.

- Focusing on reducing plastic? Coating often uses less.

We Make Your Choice Easy!

No matter which path is best for your food packaging vision – the reliable barrier of coating or the premium finish of lamination – we’ve got you covered. Our expert team provides full customization for both processes. We’ll help you select the perfect solution for your product, budget, and brand image, ensuring your packaging looks fantastic and performs flawlessly.

Ready to package your success? Let’s chat about your custom paper packaging needs!